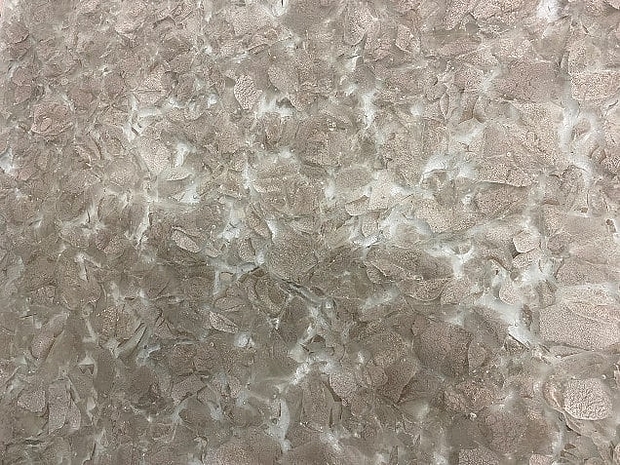

STORMY GREY

The coolest shade of MAGNA Glaskeramik

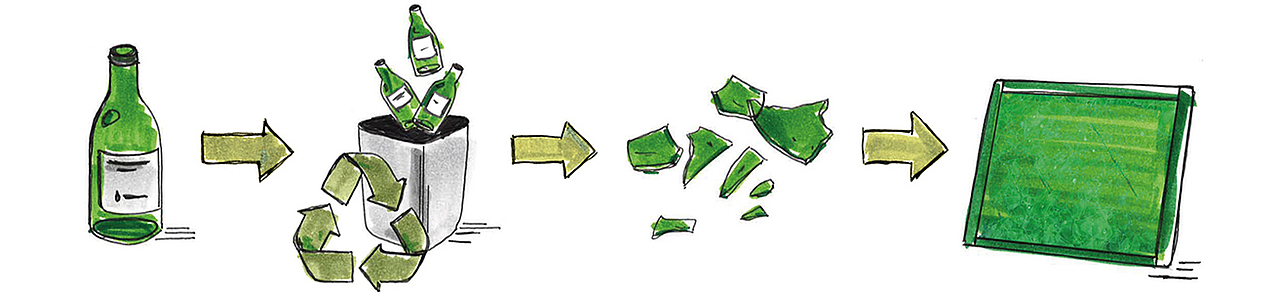

Made from the glass of specially coated solar panels from the industry. Each MAGNA Glaskeramik product is unique.

more colors

MGK x FKV

Exhibition of the Frankfurter Kunstverein: "Bending the Curve - Knowledge, Action, [Care] for Biodiversity" from 12.10.23-03.03.24

STORMY GREY was integrated into an art space installation in polished and backlit. Get one of the limited 35 quarter panels!

more infos